We have earlier extensively argued on the question of when does your supply chain really needs blockchain. We would suggest you go and have a read, especially if you are not sure whether you need blockchain in your supply chain.

Let’s say you are quite convinced that you need a blockchain solution, specifically a track and trace solution for your supply chains.

Now, what could stop you from implementing it?

Probably two major reasons you could come with:

- You don’t know if your organization is ready for blockchain.

- You are still contemplating if you could achieve track and trace capabilities without a blockchain implementation.

We will revisit No.1 later. We have a cool questionnaire to find out if your organization is ready for blockchain. You can find it at the end of this article.

But first, let’s probe if you already have an alternative to blockchain-based track and trace.

Why can’t existing digital systems, including the sophisticated ERP ones, be tweaked to perform a track and trace task for your organization?

Where is the bottleneck with these existing systems?

The problem with existing track and trace applications:

There are broadly 3 problems that prevent existing digital systems from performing a seamless track and trace task.

Problem of Accuracy

Can your existing system locate the source of execution errors in real-time? Better still, fix them.

We are talking about mistakes in inventory data, missing product info, incorrect invoices, data duplication, double payments – all these broadly falling under two categories – information and financial flows.

Your ERP systems can possibly capture these flows, but are they well-off to trace and track these errors and mark them to the appropriate physical product flows in your supply chain?

You know these mistakes have consequences. They could result in a lot of time and effort spent scrutinizing and finding out the root cause of the errors.

And if you are dealing with thousands of transactions per day, across a wide network of supply chain partners, moving a variety of products – then it makes all the sense to adopt a blockchain solution.

Problem of Communication

But even if you were to eliminate execution errors through the use of automated data capture technologies such as IoT and the like and then you were able to successfully feed them into your ERP system, the next level of problem awaits when your ERP system must communicate with ERP systems of your supply chain partners.

In which case, you might have to ask yourself how easy would this integration prove to be? Because there is a good chance that the ERP system of your partner could be totally different in the way it stores and shares the data with the outside world.

A large multi-national organization could easily have several ERP systems of their own, which itself needs integration; and then to integrate with the ERP systems of their suppliers and distributors could easily span years.

Problem of Governance

In a hypothetical scenario where you and your partners have agreed to integrate their ERP systems, but then all the while, you never gave a thought about sharing your proprietary data.

Fears such as, “what if the data that gives you a competitive edge could be passed on to your competitor” creep in.

Where do you exactly put the brakes when it comes to data sharing between your partners?

To make your supply chains visible, neither you nor your partners should be put in a blind spot. But at the same time, can organizations be fully transparent with all their information?

Blockchains to the rescue

Now do these arguments propel you to look no further than a blockchain solution? If yes, you can straightaway request a demo of the blockedge platform.

But then do you need a bit more clarity, specifically on how exactly does blockchain solve the three-fold problems of accuracy, communication, and governance?

Let’s be specific: Consider OEMs in automotive. They will have to prove the provenance of raw material or ensure that the mineral sourced is from a certified mine. During transit, they will have to make sure that products don’t go faulty as some of them could be temperature sensitive. Apart from monitoring the location during transit, it could be important to ensure that the material is exposed to only tolerant temperatures. If there is an out-of-temperature situation, the sensors attached to the raw material should alert the respective authorities for necessary corrective action.

So, in an ideal situation – you have correct data/genuine/normal-working products moving through your supply chain.

What’s the worst scenario – you have incorrect data/fraudulent products/faulty products moving through your supply chain.

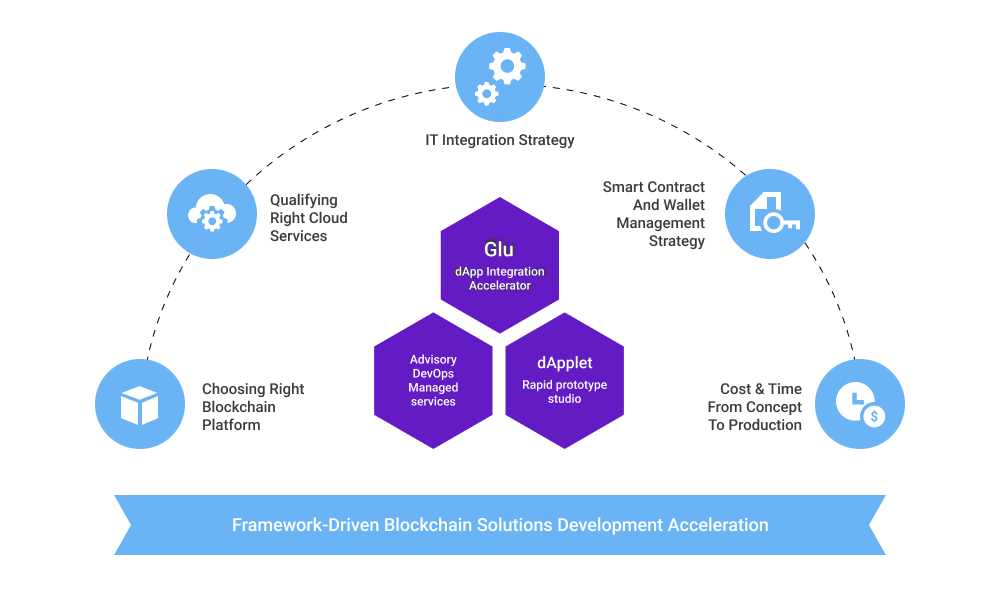

In either of these scenarios, a blockchain system records transactions in blocks and adds a timestamp to every transaction. The entries once made are immutable, meaning you can’t overwrite the past data. All authorized participants within the blockchain network will be aware of every transaction. So, nobody is put in a blind spot. If there is an error entry–there is a timestamp attached to it, so you know when exactly the error is committed.

But the elusive question – how would you track and trace the movement of the product at every step in the value chain and possibly mark the product to the relevant bill of materials, invoices, component materials, etc.?

Answer: Tokenization.

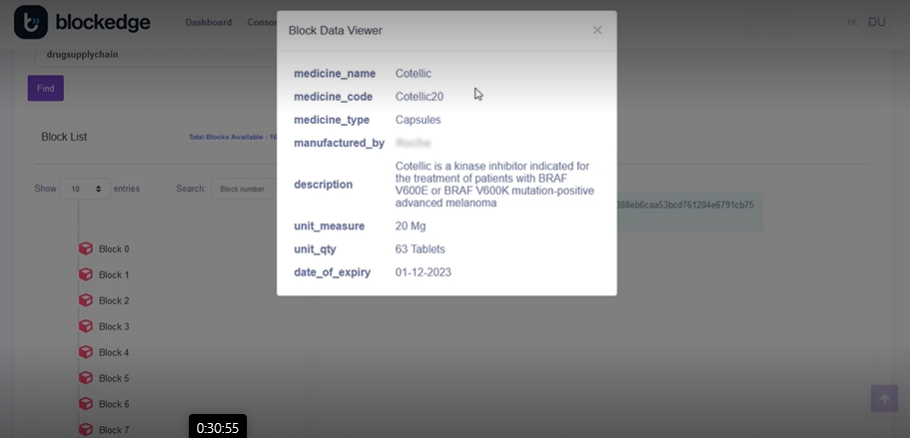

Every asset in your value chain is identified by a token. These tokens are either elemental or compound. Most primary products (minerals for instance) will be identified by an elemental token (ET). These tokens store the information of these basic products, their corresponding processes, and their origin. A group of elemental tokens (raw materials) will combine together to form a compound token (finished part). The compound tokens (CT) inherit the properties and information of their elemental tokens. Thus, the end product represented by a unique compound token will be a combination of several compound tokens. Consider the end product as a final recipe and the raw materials as ingredients. You can look at the final recipe and find out its made-up ingredients. Therefore, the inter-linkage of tokens facilitates track and trace in supply chains.

This makes more sense when we are dealing with industries where the goods transform during the manufacturing process, and the relationship between the final product and ingredients is often lost.

The same tokenization principle could be applied in industries such as pharma, where the goods don’t modify during transit. You could track and trace the provenance of a vaccine, a drug all the way to its ingredients using the same method of elemental and compound tokens.

Now that we are clear with how exactly blockchain achieves accuracy in track and trace – you might wonder how blockchain enables the communication between partners having different digital systems. It is true that blockchain is a shared ledger – distributed between participants who can access the full copy of the ledger. Within a permissioned blockchain, whenever a transaction is made, every copy will be updated, so that all the relevant parties can read the transaction.

But how would existing systems such as your ERP, warehouse management systems, and manufacturing execution systems be able to integrate with the blockchain network?

These information management systems are going to perform as usual: execute, build, track, purchase, and ship products, while you can decide between your consortia members what data would be passed into the blockchain network from these systems.

But again, how are you going to integrate these systems with your blockchain network?

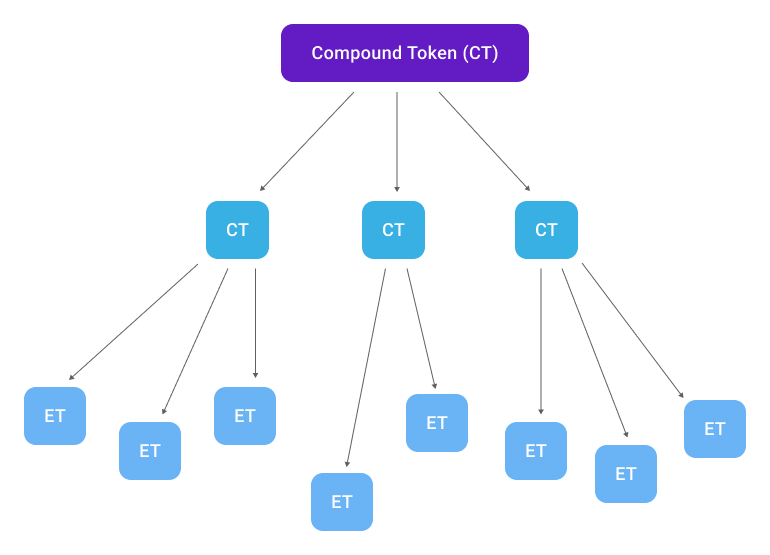

There needs to be a middleware that can connect ERP systems with your blockchain network. But the middleware needs to be seamless. At Blockedge, we have what we call a ‘Glue’ that works by receiving the necessary data through the API calls of the digital systems and sending these data into your blockchain network. Simply put, Blockedge Glue uses the API of an existing digital system to get the data into the blockchain network.

Of course, only those data that your consortia members have decided to share can be played into your blockchain network. But remember, any blockchain application is decentralized – in that case, how will you govern the secure exchange and management of data?

Blockchain advisory services from Blockedge ensure that strong anti-trust and privacy-preserving policies are in place, which allows private data fields to be hidden from others in the platform, whilst still remaining within the network. It can be made visible only to its owners while for others the particular data field can go hidden. In our track and trace application, for example, let’s say several competitors come together to track and trace a certain common raw material, all the way from the mines – only certain information pertaining to the materials origin can be tokenized and shared within the application. The consortia can decide to hide/make sensitive information such as the financial data concerning the material.

But there is more to governance than secure sharing of data. You need to take into your partners’ digital preferences. For example, your partner might be using a different cloud. You can’t simply ask them to move to a cloud that your vendor provides. If you are opting for a blockchain vendor, make sure they support multi-cloud. At Blockedge, we have support for multi-cloud and multi-chain. Let’s say, your consortia have decided to use Hyperledger. But at some point, you want to move to a different blockchain network such as Ethereum. When you have multi-chain support, that migration becomes easy.

Blockedge enables to create and manage consortia at ease. Most importantly, you have a zero-code framework, which means you don’t need extensive technical resources to implement blockchain applications. We have what we call dApplets for rapid dApps prototyping. Because when you are working on a decentralized application (dApp), there could be rapid requirement changes in your use case. A blockchain vendor that promises customized development of dApps could prove to be costly as the use cases might be constantly getting finetuned. Sometimes, you could totally desert a particular use case and move on to another. Blockedge provides that flexibility, it gives a rapid prototyping studio where you could first visualize your use case before getting into full swing with the actual implementation.

So, we have explained to you how blockchain, specifically Blockedge, could help you with a supply chain application such as track and trace. Three important considerations:

- How are you going to ensure accuracy with your data?

- How are you going to ensure communications between systems of your supply chain partners?

- How are you going to govern and manage the consortia?

So, with that, we have put the ball in your court. It is time to find out how ready are you for blockchain?

Start your blockchain implementation with a readiness assessment.

See you on the other side!